WHEEL AND DOLLY SETS:

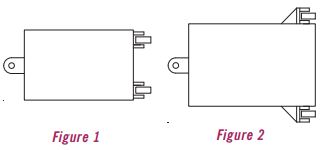

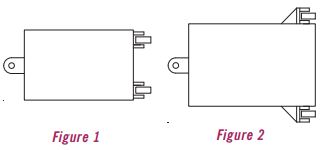

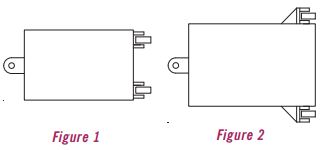

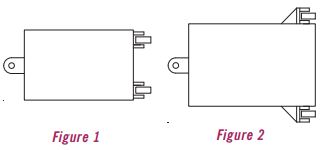

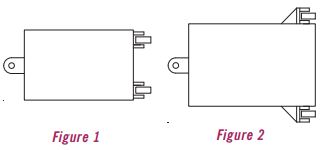

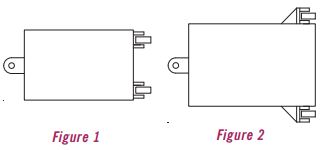

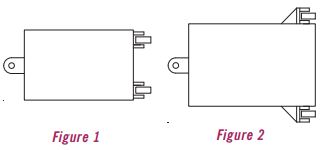

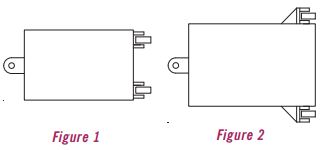

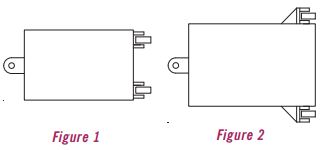

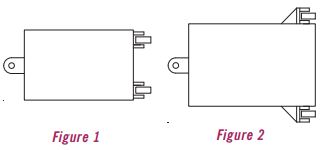

These are only used to move empty units. Standard pricing is for units with minimum size platforms and end mounted wheels as shown in (Fig 1.)

Standard ground clearance is 1/2″. Side mounted wheels (Fig. 2) may be special ordered. Special kits for other than minimum size platforms may also be available if you consult the factory

CASTER SETS:

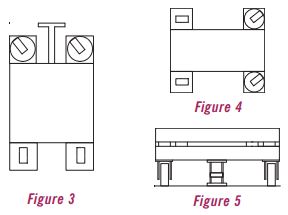

These are designed so that loaded lifts can be moved with no damage to the lifts or casters. It should be remembered however, that a 2000# load on a lift presents as much inertia to overcome as a car does and as the capacity of the lifts go up, it becomes increasingly difficult to move a fully loaded unit. Units are equipped with two fixed and two swivel casters to aid steering. Ground clearance varies by unit and caster configuration, but is always at least 1″. The standard configuration is end mount (Fig. 3), but side mount (Fig. 4) and bottom mount (Fig. 5) are also available

FLANGED OR “V” GROOVE WHEEL SETS:

These guided wheel sets can be mounted in any of the three configurations shown for the caster sets. The flanged wheels typically ride 1/2″ by 1-1/2″ flat tracks and the ‘V” groove wheels typically ride 1-1/2″ by 1-1/2″ inverted angle iron tracks. Higher capacities require larger tracks.

WHEEL AND DOLLY SETS:

These are only used to move empty units. Standard pricing is for units with minimum size platforms and end mounted wheels as shown in (Fig 1.)

Standard ground clearance is 1/2″. Side mounted wheels (Fig. 2) may be special ordered. Special kits for other than minimum size platforms may also be available if you consult the factory

WHEEL AND DOLLY SETS:

These are only used to move empty units. Standard pricing is for units with minimum size platforms and end mounted wheels as shown in (Fig 1.)

Standard ground clearance is 1/2″. Side mounted wheels (Fig. 2) may be special ordered. Special kits for other than minimum size platforms may also be available if you consult the factory

WHEEL AND DOLLY SETS:

These are only used to move empty units. Standard pricing is for units with minimum size platforms and end mounted wheels as shown in (Fig 1.)

Standard ground clearance is 1/2″. Side mounted wheels (Fig. 2) may be special ordered. Special kits for other than minimum size platforms may also be available if you consult the factory

WHEEL AND DOLLY SETS:

These are only used to move empty units. Standard pricing is for units with minimum size platforms and end mounted wheels as shown in (Fig 1.)

Standard ground clearance is 1/2″. Side mounted wheels (Fig. 2) may be special ordered. Special kits for other than minimum size platforms may also be available if you consult the factory

WHEEL AND DOLLY SETS:

These are only used to move empty units. Standard pricing is for units with minimum size platforms and end mounted wheels as shown in (Fig 1.)

Standard ground clearance is 1/2″. Side mounted wheels (Fig. 2) may be special ordered. Special kits for other than minimum size platforms may also be available if you consult the factory

WHEEL AND DOLLY SETS:

These are only used to move empty units. Standard pricing is for units with minimum size platforms and end mounted wheels as shown in (Fig 1.)

Standard ground clearance is 1/2″. Side mounted wheels (Fig. 2) may be special ordered. Special kits for other than minimum size platforms may also be available if you consult the factory

WHEEL AND DOLLY SETS:

These are only used to move empty units. Standard pricing is for units with minimum size platforms and end mounted wheels as shown in (Fig 1.)

Standard ground clearance is 1/2″. Side mounted wheels (Fig. 2) may be special ordered. Special kits for other than minimum size platforms may also be available if you consult the factory

WHEEL AND DOLLY SETS:

These are only used to move empty units. Standard pricing is for units with minimum size platforms and end mounted wheels as shown in (Fig 1.)

Standard ground clearance is 1/2″. Side mounted wheels (Fig. 2) may be special ordered. Special kits for other than minimum size platforms may also be available if you consult the factory

WHEEL AND DOLLY SETS:

These are only used to move empty units. Standard pricing is for units with minimum size platforms and end mounted wheels as shown in (Fig 1.)

Standard ground clearance is 1/2″. Side mounted wheels (Fig. 2) may be special ordered. Special kits for other than minimum size platforms may also be available if you consult the factory

WHEEL AND DOLLY SETS:

These are only used to move empty units. Standard pricing is for units with minimum size platforms and end mounted wheels as shown in (Fig 1.)

Standard ground clearance is 1/2″. Side mounted wheels (Fig. 2) may be special ordered. Special kits for other than minimum size platforms may also be available if you consult the factory

GATES & ENCLOSURES:

We are now manufacturing our own gates and enclosures. By moving the production of the gates and enclosures in house we have shortened our drawing and delivery times. Besides the quicker delivery times, this has allowed us to incorporate some design changes that will improve the fit and finish and make installation easier. The most noticeable change will be the incorporation of leveling feet. Besides making it very easy to deal with un-level floors, they also make it easier to adjust for small surprises like mezzanine lag bolts.

BI-PARTING SWING GATE

OPTIONAL

OPTIONAL

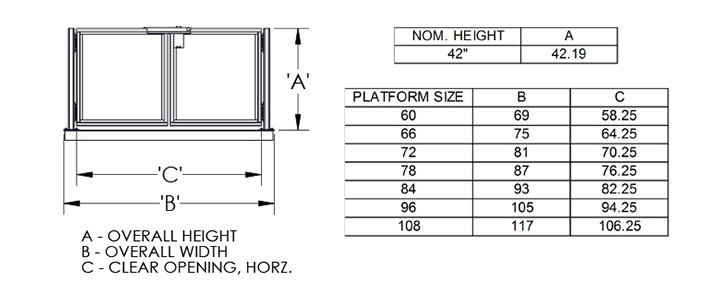

HORIZONTAL SLIDING GATE, MEZZANINE

OPTIONAL

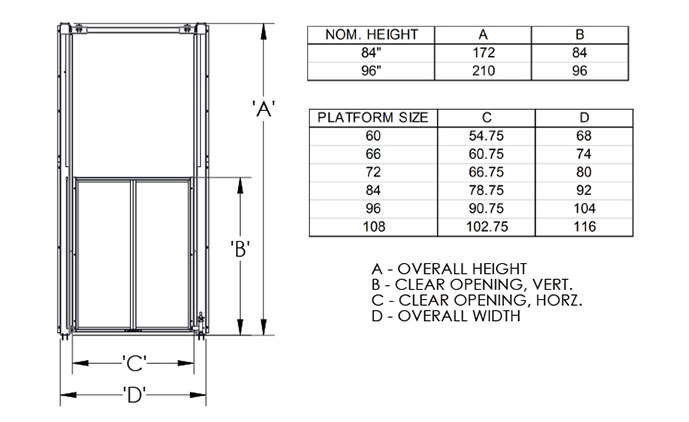

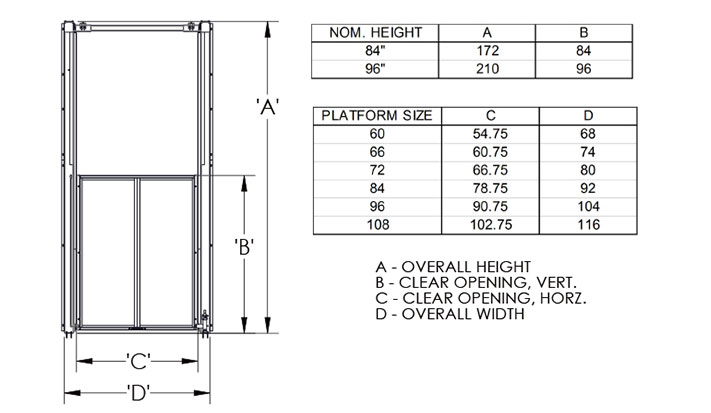

SINGLE PANEL VERTICAL SLIDING GATE

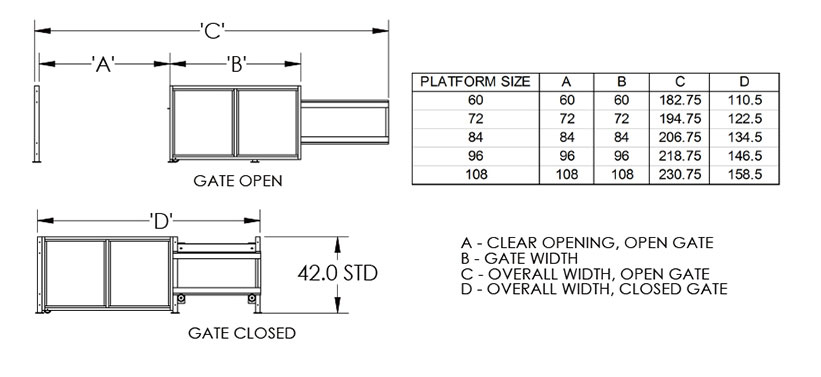

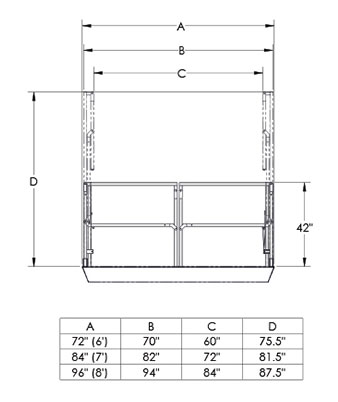

BI-PARTING GATES:

Our bi-parting gates are available in standard widths of 6’, 7,’ or 8’. See chart for exact dimensions. The gates are held in the upright position by gas air springs. Electrical interlocks are optional.

- Bi parting gate for 6 ft side with 52” clear width

- Bi parting gate for 7 ft side with 64” clear width

- Bi parting gate for 8 ft side with 76” clear width

CONTROLS:

FIG. 1 – NEMA 4X pushbutton (Standard)

FIG. 2 – NEMA 1 wall mount pushbutton

FIG. 3 – up DOWN key operated

FIG. 4 – push Button With key Lockout

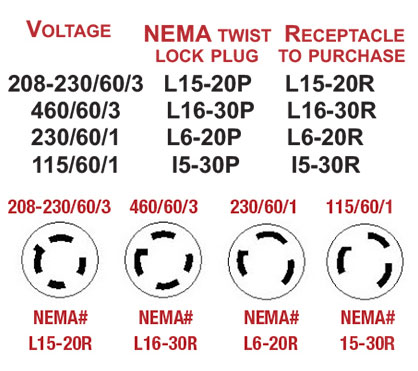

FACTORY STANDARD RECEPTACLE CHARTS:

Standard voltage for all power units of 1hp or larger is 230/60/3. These units will operate on 208, 220, 230, 240 voltages and if the magnetic overloads are changed, they can be rewired to operate on 440, 460, and 480 voltages also.