Spending 20 minutes to match order specifications to verified site conditions can insure a smooth trouble free installation and possibly save all parties involved from expensive mistakes. The inspection should be conducted in a meeting with the user and the salesman and whenever possible the installer. If the installer is not available, the salesman should prepare notes for the installer.

- Materials needed: Order, quotation with specifications, installation drawings (can be catalog typical drawings for standard models), measuring tape, 3 foot level and note taking supplies.

- Verify that all items on the order, quotation, specifications and drawings match exactly with no discrepancies.

- If a pit is poured for a recessed installation, verify all pit dimensions checking the depth in several areas to be sure it is correct and even. Measure the diagonals of the pit to be sure that the pit is square and not a parallelogram. Check dimensions on any recesses for bridges or optional chocks. Use the level to check levelness of the floor and be sure to check where the base frame will need to be supported. Unsupported base frames will deflect under heavy loads causing the loading dock lift to wobble, so installers must be prepared to shim and grout under base frames to keep them fully supported. Check for pit drains and hose chases.

- If the application is for a top of ground unit then check the pad for size and levelness. Also note flatness so the installer knows how much shim and grout to bring.

- Check the location of the bollards or other truck restraints to be sure the specified bridge will reach into trucks 4” to 6”.

- If the power unit is not mounted on the loading dock lift, check the proposed power unit location and whether the power unit will sit on the ground or be mounted on a wall. Be sure enough hose was ordered to reach from the lift to the power unit.

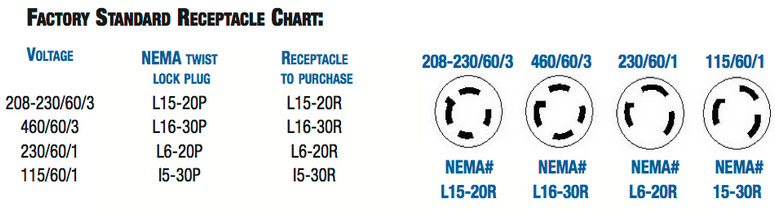

- Check the location voltage of the power source and verify that it matches the voltage that was ordered. If twist lock plugs or other connecting devices are being used be sure the proper plug on site matches the mating plug from Advance Lifts.

- Check the control location and cord requirements so that the control can be used by the operator on the lift.

- Verify with the user that when the unit is delivered, there will be no access problems for off -loading and installing.