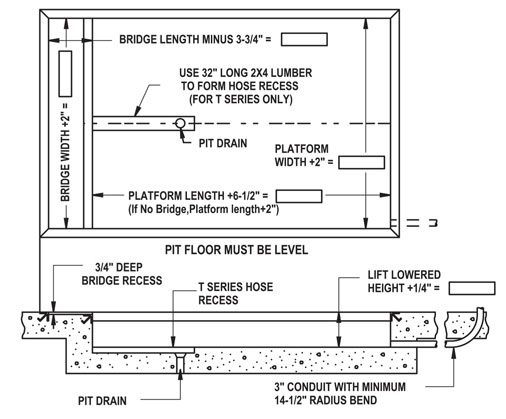

WHERE BRIDGE WIDTH IS THE SAME AS PLATFORM WIDTH

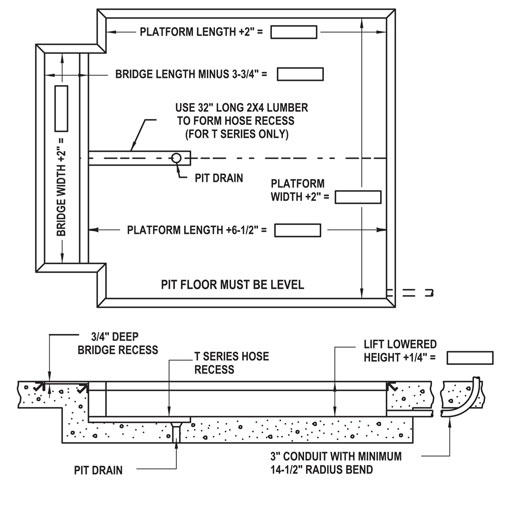

WHERE BRIDGE WIDTH IS SMALLER THAN THE PLATFORM WIDTH

NOTES

A Consult factory for pit diagram for optional wheel chock.

B Reinforce concrete to suit local soil conditions.

C All pit work and materials shown are the responsibility of owner or his agent (by pit contractor).

D Installer to run 1/2″ diameter hose(s) and plastic tubing through 3″ conduit from power unit to lift base.

E Dimension tolerances are plus 1/4″ minus 0″ (+1/4″-0″).

F 180º steel hinge bridges require a bridge recess length equal to bridge length minus 2-3/4″.

G 180º aluminum hinge bridges require a bridge recess length equal to bridge length minus 3-3/4″ and a pit length equal to platform length plus 7-1/2″.

H Consult factory for bridges longer than 30″. (18″ on 4000 Series).

INSTALLATION BILL OF MATERIALS

1 3″ x 3″ x 1/4″ curb angle as required.

2 One (1) 3″ conduit from power unit location to pit.

3 One (1) Advance Model __________.

4 One (1) electric disconnect switch for 5HP or 7-1/2HP motor.

5 ( ______) gallons of ISO46 hydraulic fluid.

6 One (1) 1/2″ SAE 100R2 hydraulic pressure hose from power unit location to lift base – 1/2″ female #8JIC threads both ends +1/4″ O.D. plastic tubing (two hoses required for 4000 Series Safetydok).

7 Concrete anchor bolts and material for shimming and/or grouting.

*seller furnishes Advance dock lift only unless otherwise agreed to in writing.

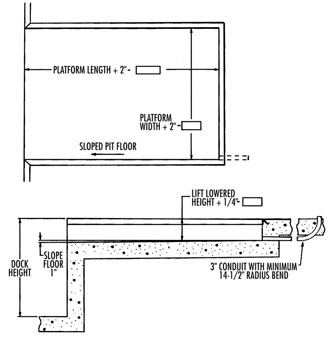

TOP OF DOCK RECESSED INSTALLATION 3 SIDED PIT

TOP OF DOCK INSTALLATION BILL OF MATERIALS

1 3″ x 3″ x 1/4″ curb angle as required.

2 One (1) 3″ conduit from power unit location to pit.

3 One (1) Advance Model _______.

4 One (1) electric disconnect switch for 5HP or 7-1/2 HP motor.

5 (________) gallons of ISO46 hydraulic fluid.

6 One (1) 1/2″ SAE 100R2 hydraulic pressure hose from power unit location to lift base 1/2″ female #8JIC threads both ends (two hoses required for 4000 Series).

7 Concrete anchor bolts and material for shimming and/or grouting.

*seller furnishes lift only unless otherwise agreed to in wri

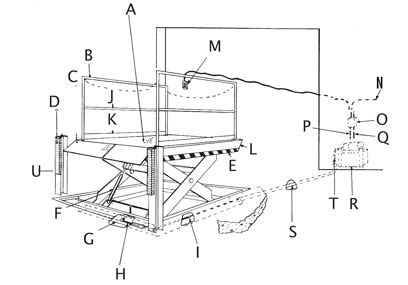

TYPICAL RECESSED DOCK LIFT INSTALLATION AT A RAISED DOCK

TYPICAL RECESSED DOCK LIFT INSTALLATION AT GROUND LEVEL

A Platform with Safety Tread Deck

B Removable Handrails with Safety Chains

C Hinged Bridge

D Rubber Dock Bumpers

E Black and Yellow Safety Striping

F Chrome Plated Rams

G Pre-Drilled Base Frame for Lagging Lift to Floor

H 48″ long Hydraulic Connecting Hose supplied by Advance Lifts, Inc. with 1/2″ Connector at center of base frame. Optional: 1/2″ x 20′ long Hydraulic Hose supplied by Advance Lifts, Inc

I Connector

J Midrail

K Kickplate

L Bevel Toe Guards 4-Sides

M Up-Down Pushbutton Station NEMA 1, 3, 3R, 4, 4X W/20′ Control Cord

N Incoming Power Source

O Motor Controller in NEMA 12 Enclosure

P To Motor on Power Unit

Q To Down Solenoid on Power Unit

R Power Unit 5 HP 230V 60Hz 3Ph motor mounted on Reservoir 26″ W x 22″ L x 21″ H (including motor) with brackets for wall mtg.

S Run 3″ Conduit from Power Unit Location to Lift Base (by others)

T Installer to run 1/2″ Hydraulic 100R2 Hose through and Plastic Return Line 3″ Conduit from Power Unit to Connecting Hose and Tub

U WF Beam or Dock face